Staircase fitted prior to screed installation

We can even screed under existing staircases

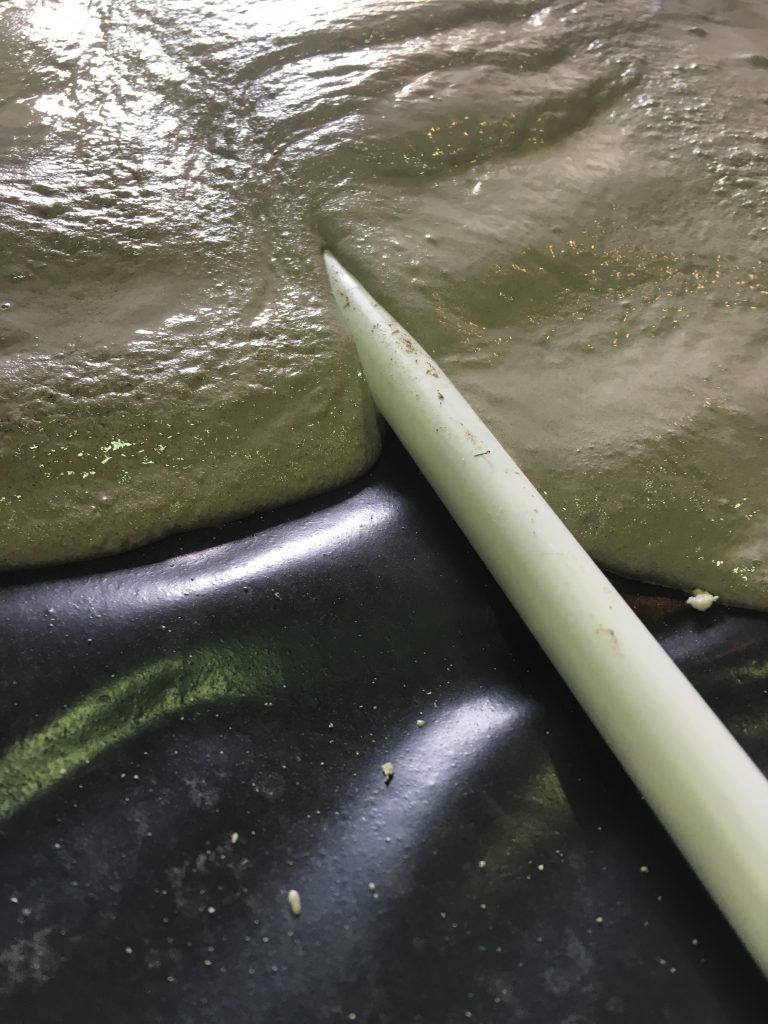

Screed being layed over an UFH system

Screed surrounds UFH pipe to provide best possible thermal conductivity

Local Restaurants and Shopping centres fitted with Gypsum Screed

The ability to screed next to painted walls allows the consumer to speed up the build, or to be able to renovate without re-painting

There are many different types of screed products available on the market, each one depending on application

Gypsum based screeds are the ideal solution for any under floor heating application as they prove to be 30% more efficient in comparison to traditional dry screeds

Screeds can be layed to an SR2 accuracy ensuring your floor is as level and smooth as possible, which enables very simple floor coverings without the need for self leveller or excessive tile adhesive.

Screeds can be layed in a bonded or an un-bonded form

Bonded screeds can be placed down at a thickness from as little as 10mm which enables the consumer to level out any floor which is uneven or rough without the need for a thick floor covering or where height restrictions are limited in the application

Un-bonded floors can be placed down at a thickness of 35mm and above, or where Under Floor Heating is present, 50mm and over ensuring fast heat up times and maximum efficiency for traditional boilers or for any of the renewable energies.

Screed finishes are only suitable for indoor use and can be walked on within 24-48 hours (weather and temperature dependant) and will be ready for non-load bearing walls to be erected within 7 days